- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

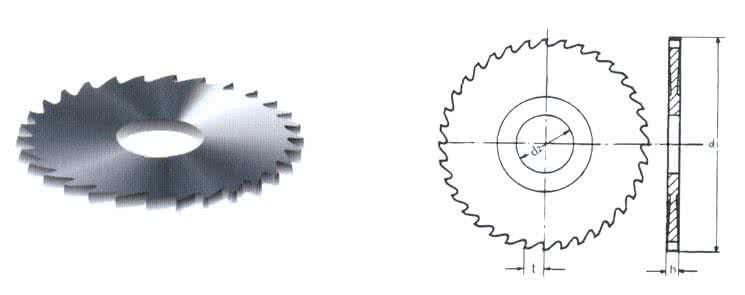

Customized Carbide saw blade

Customized Carbide saw blade

40 x0,1 x 10 mm, Z=128 A1

20 x0,7 x5 mm, Z=48 A1

63 x0,4x 16 mm,Z=64 B1

100 x 1,2 x22 mm, Z=128 A1

High Quality Tungsten Circular Carbide Saw Blade Round Metal Cutter For Metal Machining

Product Features :

1. Long life with supper resistance to heat, wear and abrasion.

2.Good finish:milling line speed high finish better

3.Efficient:high-speed milling processing speed can be greatly improved.

Advantages:

1 High quality, supper sharp/,smooth cutting ,long working life

2 100% raw material, HIP-Sintered

3 CNC grinding for teeth, with high precision

4 Various grades for different kinds of cutting material

5 Strict quality control, complete test equipments

6 Competitive price

7 Good after sale service

| External diameter(D) | Thickness(H) | Inner diameter(d) | Teet(T) |

| 25 | 0.2--5.0 | 6 8 10 | 10--58 |

| 30 | 0.2--5.0 | 6 8 10 | 10--60 |

| 32 | 0.2--6.0 | 6 8 10 12.7 | 10--60 |

| 35 | 0.2--6.0 | 8 10 12.7 | 10--60 |

| 40 | 0.2--6.0 | 8 10 12.7 | 10--80 |

| 45 | 0.2--8.0 | 10 12.7 16 | 10--80 |

| 50 | 0.2--8.0 | 10 12.7 16 | 10--100 |

| 55 | 0.2--8.0 | 12.7 16 | 24--120 |

| 60 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 63 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 70 | 0.3--8.0 | 16 22 25.4 | 28--120 |

| 75 | 0.5--8.0 | 16 22 25 4 | 30--120 |

| 80 | 0.5--8.0 | 22 25.4 | 30--128 |

| 85 | 0.5--8.0 | 22 25.4 | 30--128 |

| 90 | 0.5--8.0 | 22 25.4 | 30--160 |

| 100 | 0.5--8.0 | 22 25.4 27 | 30--160 |

| 110 | 0.8--8.0 | 22 25.4 27 32 | 30--180 |

| 120 | 1.0--10.0 | 22 25.4 27 32 | 30-240 |

| 125 | 1.0--10.0 | 22 25.4 27 | 30-240 |

| 150 | 1.0--10.0 | 22 25.4 27 32 | 40-240 |

C) TRS greater than or equal to 3800 N/mm²;

Loaʻa i ka hui kahi laina hana hana ʻenehana piha mai ka pauka maka mea hoʻomākaukau, hana ʻia, kaomi ʻana, kaomi sintering, wili, ka uhi a me ka uhi ʻana ma hope o ka mālama ʻana. Hoʻopili ia i ka noiʻi a me ka hana hou o ka waihona kumu, ka hoʻolālā groove, ka hoʻokumu pololei ʻana a me ka uhi ʻana o ka carbide NC inserts, a hoʻomaikaʻi mau i ka hana machining, ke ola lawelawe a me nā waiwai ʻoki ʻē aʻe o ka carbide NC inserts. Ma hope o ʻumi mau makahiki o ka noiʻi ʻepekema a me ka hana hou, ua ʻike ka hui i nā ʻenehana kumu kūʻokoʻa, loaʻa iā R&D kūʻokoʻa a me nā mana hoʻolālā, a hiki ke hāʻawi i ka hana maʻamau no kēlā me kēia mea kūʻai.