- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

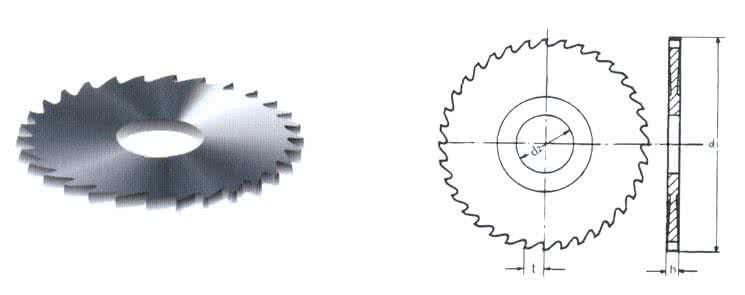

Customized Carbide saw blade

Customized Carbide saw blade

40 x0,1 x 10 mm, Z=128 A1

20 x0,7 x5 mm, Z=48 A1

63 x0,4x 16 mm,Z=64 B1

100 x 1,2 x22 mm, Z=128 A1

High Quality Tungsten Circular Carbide Saw Blade Round Metal Cutter For Metal Machining

Product Features :

1. Long life with supper resistance to heat, wear and abrasion.

2.Good finish:milling line speed high finish better

3.Efficient:high-speed milling processing speed can be greatly improved.

Advantages:

1 High quality, supper sharp/,smooth cutting ,long working life

2 100% raw material, HIP-Sintered

3 CNC grinding for teeth, with high precision

4 Various grades for different kinds of cutting material

5 Strict quality control, complete test equipments

6 Competitive price

7 Good after sale service

| External diameter(D) | Thickness(H) | Inner diameter(d) | Teet(T) |

| 25 | 0.2--5.0 | 6 8 10 | 10--58 |

| 30 | 0.2--5.0 | 6 8 10 | 10--60 |

| 32 | 0.2--6.0 | 6 8 10 12.7 | 10--60 |

| 35 | 0.2--6.0 | 8 10 12.7 | 10--60 |

| 40 | 0.2--6.0 | 8 10 12.7 | 10--80 |

| 45 | 0.2--8.0 | 10 12.7 16 | 10--80 |

| 50 | 0.2--8.0 | 10 12.7 16 | 10--100 |

| 55 | 0.2--8.0 | 12.7 16 | 24--120 |

| 60 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 63 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 70 | 0.3--8.0 | 16 22 25.4 | 28--120 |

| 75 | 0.5--8.0 | 16 22 25 4 | 30--120 |

| 80 | 0.5--8.0 | 22 25.4 | 30--128 |

| 85 | 0.5--8.0 | 22 25.4 | 30--128 |

| 90 | 0.5--8.0 | 22 25.4 | 30--160 |

| 100 | 0.5--8.0 | 22 25.4 27 | 30--160 |

| 110 | 0.8--8.0 | 22 25.4 27 32 | 30--180 |

| 120 | 1.0--10.0 | 22 25.4 27 32 | 30-240 |

| 125 | 1.0--10.0 | 22 25.4 27 | 30-240 |

| 150 | 1.0--10.0 | 22 25.4 27 32 | 40-240 |

C) TRS greater than or equal to 3800 N/mm²;

Konpayi an gen yon liy pwodiksyon ekipman pwosesis manifakti lam konplè soti nan preparasyon poud matyè premyè, fè mwazi, peze, presyon SINTERING, fanm k'ap pile, kouch ak kouch apre-tretman. Li konsantre sou rechèch la ak inovasyon nan materyèl la baz, estrikti Groove, fòme presizyon ak kouch sifas nan foure carbure NC, ak toujou ap amelyore efikasite nan machin, lavi sèvis ak lòt pwopriyete koupe nan foure carbure NC. Apre plis pase dis ane nan rechèch syantifik ak inovasyon, konpayi an te metrize yon kantite teknoloji debaz endepandan, gen endepandan R & D ak kapasite konsepsyon, epi li ka bay pwodiksyon Customized pou chak kliyan.